These Planes are versions of rctestflight’s Micro Drone v3. They have larger wingspans (both 30 inches) and the kf step is made from insulation foam instead of foam board. For increased efficiency, I’m running an 810kv motor with a 10×4.7 prop on a 2s battery. I get around 15 minutes of flying with this setup.

Tag Archives: KF airfoil

24” Flying Wing (stepped airfoil)

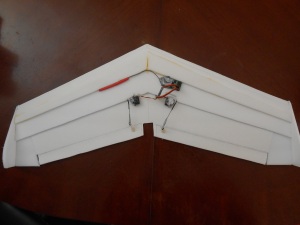

I started this project simply to have a small crash-resistant plane that I could fly in my front yard. For the first time, I looked into flying wings for the design. All I knew was that they could be more efficient and were a little faster. After a bit of research, I learned that they had quite a few advantages over traditional plane designs. Stepped KF airfoils also offer quite a few advantages over traditional airfoils. I’ll discuss what I learned and give a quick build log on my 24” flying wing.

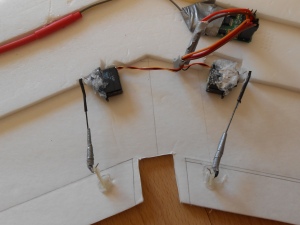

I wanted to keep the wing as light as possible. I had some 2.5g servos lying around, so I soldered standard PWM cables to the wires that came stock with mini JST connectors with signal, ground, power from left to right. Soldering proved to be quite a challenge, as micro servos have extremely small wire. I don’t know how much current these 2.5g servos draw, but it can’t be more than .25 amps. To get the insulation off I just clamped down on the ends of the wire with my fingernails and tugged it loose. This works quite well.

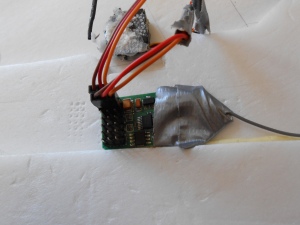

Mounting the receiver just took a little hot glue:

I just hot-glued the receiver to the 2nd step. It’s placement shouldn’t affect the wing aerodynamically, as it is rather small.

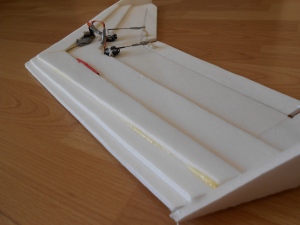

Also glued in the ailerons. I never got a chance to take pictures of the motor and battery after they were mounted, but those steps are self-explanatory. I made it a tractor, because I didn’t want to have to deal with CG issues if I moved the motor to the back for a pusher configuration.

The aileron servos should be squared up, perpendicular to the control surface. Mine aren’t, because I was in a hurry. If you do ’em right, you’ll have perfect throw on both ailerons. I had to adjust them a little with my radio.

I never thought that sweep angle on a wing could be as intricate of a subject as it is- There are many factors that contribute to the performance of the wing to consider. The most important consideration is drag- the sharper the angle, the less drag, which results in a faster wing. I went with a mild 140 degrees for a little more drag to slow it down enough to fly in my front yard, which is rather small.

With a protractor I drew a 140 degree angle on a full sheet of foam board. I wanted my overall span to be 24” but I didn’t know what wing chord to use. For aesthetics’ sake, I chose 10”. In the future, I’ll just wing it (pun intended)- after two very different chords I found no significant change in performance.

The first KF step is 1/2 of the entire wing. I just laid it down on the remainder of the sheet of foam board and traced- then I split it in half and glued it onto the wing, offset 1/4” inch. I don’t know why exactly I did this, but I felt that a gradual sweep was needed- maybe I felt it necessary to emulate the profile of a traditional airfoil- what I did know was that there was nothing aerodynamically responsible about having a wall of foam before the KF step.

After putting it all together, I did a few test taxis around my driveway. It lasted 5 flights before I accidentally landed it into a tree.

RIP, 24” flying wing

Use the pictures for reference if you want to build one!